Quality

At China Swiss CNC Machining, the application of quality start with each new part. We have a formal new product introduction (NPI) and launch process. A cross functional team reviews all aspects of a new part and depending on the complexity, a design review with the customer is also part of the process. Using a Stage-Gate System for NPI guarantees the manufacturing concept is set up as a documented process. Sometimes we have parts in development and are run through the prototype cell. Click here to go to prototype cell

Dedicated Project Engineer Assigned

We understand the importance of planning and coordinating the manufacture of a new series of parts. We have dedicated project engineers responsible for the planning and implementation of a project. In collaboration with several departments, they create the manufacturing process, release an inspection schedule, coordinate, and monitor the work. Our goal is to consistently push the limits of machining technology. If you have a new design that you would like to discuss, please contact us either by email or clicking on the Request a Quote above right.

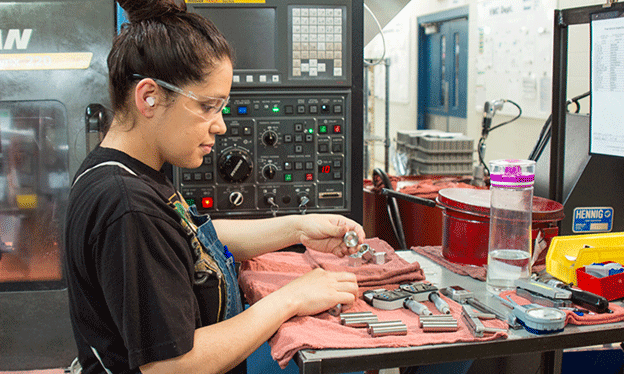

In Process / Quality at the Source

- Infinity QS SPC Software

- SPC on “Key” Process Characteristics

- In Process Inspection based on Tool Path & Wear

Quality You Can Depend On

Operator Measuring Part In Process

Continuous Improvement

- Dedicated Resources

- Structured Process Improvement Systems

- Utilize DMAIC Process

- Daily Gemba Reviews

Inspection Equipment Includes:

- Oasis Automated Part Inspection System

- Keyence IM-7020 Automated Part Inspection System

- Starrett Digital Video Systems

- Zeiss O-Inspect CMM and Optical CMM

- Laser Micrometer

- Surface Profilometer

- Air Gaging and Bore Gaging

Our State-of-the-Art Inspection System

Image: Keyence IM-7020 Automated Part Inspection System