Fully trained in-house maintenance technicians keep equipment up and running. This enables capacity planning, provides control over preventative maintenance, and saves on overall down time. We send our technicians for training at regular intervals or when a new course is offered from the equipment manufacturers.

Machining

China Swiss CNC Machining utilizes the latest proven technologies in Swiss machining, CNC milling, in-house passivation, surface grinding, and inspection equipment. China Swiss CNC Machining’s state of the art 45,000 square foot manufacturing facility houses CNC Swiss Machines, CAM Swiss Machines, CNC Turning Machines, CNC Milling Machines and Finishing/Deburring/Polishing.

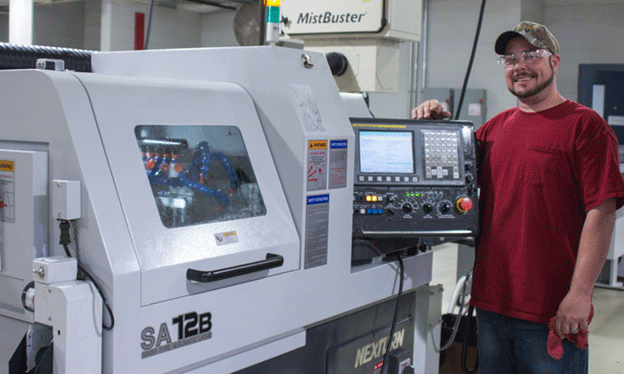

Prototype Cell

Boasts 2 NEXTURN SA(PYII) Machines

Information Technologies

China Swiss CNC Machining Inc runs on state of the art, fully integrated Epicor 10 software. Jobs can be tracked real time on the production floor. Our ERP System drives our business. Having all the necessary documentation to produce a part or fulfill an order in one location is a great benefit to our company and our customers.

China Swiss CNC Machining has a Well-Equipped, Comprehensive Quality Lab, including an Optical CMM with touch probe capabilities and an Ultra-High Precision Laser Scan Micrometer. We also use an Oasis Optical Profiler, as well as other Optical Comparators and Gages on the production floor.

Sporting an elongated bar feeder that can handle runs of up to 12 feet in length, the NEXTURN SA12B offers better control of bar material. It can also greatly reduce the amount of waste material that results from cutting longer bars to fit shorter feeders.